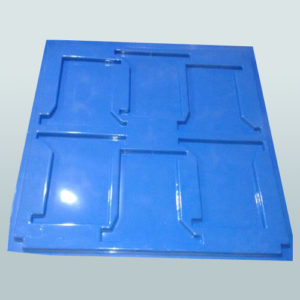

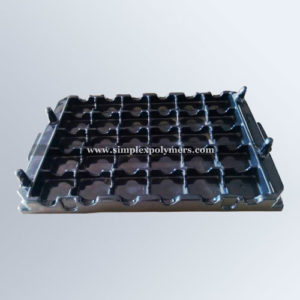

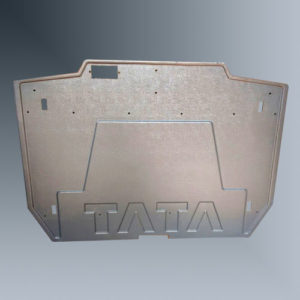

Vacuum Forming

Thermo or ‘Vacuum forming’ is one of the oldest and most common methods of processing plastic materials. Vacuum formed products are all around us and play a major part in our daily lives.

The process involves heating a plastic sheet until soft and then draping it over a mould. A vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the mould. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic, hydraulic and heat controls thus enabling higher production speeds and more detailed vacuum formed applications.